High Purity Sterile Waters

Sterile, High-Purity Waters to Streamline Workflows and Accelerate Innovation

is your trusted partner for sterile water solutions, encompassing the full spectrum of USP compendial purified waters (Sterile Water for Injection, Sterile Purified Water, Sterile Water for Irrigation, etc.) through our

is your trusted partner for sterile water solutions, encompassing the full spectrum of USP compendial purified waters (Sterile Water for Injection, Sterile Purified Water, Sterile Water for Irrigation, etc.) through our

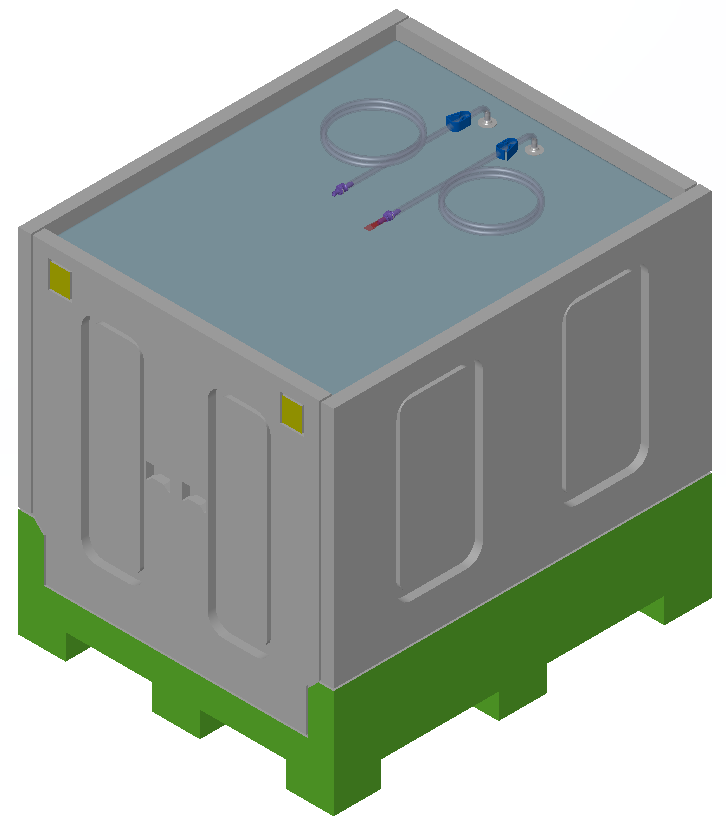

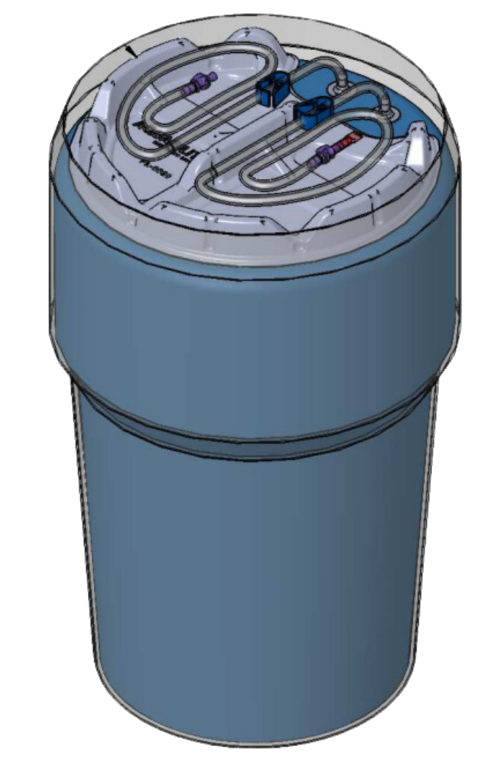

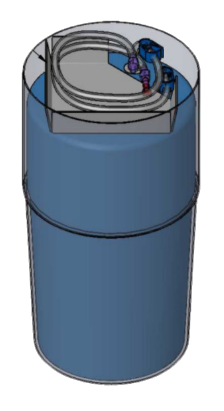

portfolio and available in customizable single-use bulk bioprocess containment systems. As a preferred Water for Injection quality water supplier of USP/EP grade WFI,

portfolio and available in customizable single-use bulk bioprocess containment systems. As a preferred Water for Injection quality water supplier of USP/EP grade WFI,

is committed to providing the highest purity waters – made possible by our state-of-the art generation system specifically designed for large scale production of continuously monitored ultra-pure water, along with end-to-end control of filling and packaging via in-house single-use systems manufacturing.

is committed to providing the highest purity waters – made possible by our state-of-the art generation system specifically designed for large scale production of continuously monitored ultra-pure water, along with end-to-end control of filling and packaging via in-house single-use systems manufacturing.

Available in customizable, single-use formats, our compendial waters integrate seamlessly into aseptic processing, sterile drug production, and cleanroom operations – delivering the reliability and flexibility your critical applications require.

Features of our high purity sterile waters —

Multiple Packaging Options Available

Readily Available

Compliant with Compendial (USP/EP) Specifications and Requirements

Custom Manufacturing Available

Leverage Out Continuous Manufacturing Capabilities to Your Advantage

Environmentally Conscious

Cost-Effective

Sterile, quality waters to enhance your workflow and hyper-accelerate new projects

Standard packaging options: Stocked standard packaging options are readily available for shipping in as little as 3 days providing a reliable, long-term supply.

Custom, single-use formats: Fully customized SUS bioprocessing containers and components are expeditiously designed by our in-house product development team and manufactured within 2 to 3 weeks*. They are then filled per customer lot size and testing requirements. Compared to all other providers who outsource manufacturing of their SUS with lead times of months, we have the industry-lowest lead times.

Cost effectiveness: Due to efficiency and skill in SUS manufacturing, our overhead is low allowing us to pass the savings onto customers and offer industry-best pricing on all of our sterile water products.

*For commonly sourced components

State-of-the-Art Water System

Commissioned in 2023, our high-capacity on-demand reverse osmosis water generation system was specifically designed with a series of purification processes including activated carbon filtration, dual UV treatment, continuous electrodeionization, and ultrafiltration with a 0.05-micron filter to achieve ASTM Type 1A water – the highest purity water reserved for the most critical applications – a claim that few water systems can make. To maintain compliance with ASTM Type 1A water, conductivity and TOC are continuously monitored via online controls, while endotoxin and bioburden are tested weekly.

Our innovative water generation system is tankless and allows for closed-loop, continuous manufacturing with lot sizes far exceeding those restrained to a storage tank. Along with utilizing endless loop technology and 100% SUS post Point-Of-Use of the water system, we’ve eliminated any risk of contamination while significantly reducing extensive cleaning requirements – allowing us to pass further savings onto the customer.

| Water Type | Conductivity (µS/cm) | TOC (ppb) | Endotoxin (EU/mL) | Heterotrophic Bacteria Count |

|---|---|---|---|---|

Generated Generated |

≤ 0.06 | ≤ 20 | ≤ 0.01 | 0 CFU / 100mL |

| ASTM Type 1A Water | ≤ 0.056 | ≤ 50 | ≤ 0.03 | ≤ 10 CFU / 1000mL |

Post-packaging, our sterile waters not only meet but significantly exceed USP specifications and USP/EP specifications (AQUAPure HYPER WFI).

| Water Type | Conductivity (µS/cm) | TOC (ppb) | Endotoxin (EU/mL) | Heterotrophic Bacteria Count | Particulate Matter (Particles/mL) | |

|---|---|---|---|---|---|---|

| ≤25 µm in size | ≤10 µm in size | |||||

's 's

WFI WFI

|

≤ 3 | ≤ 3 | ≤ 0.01 | 0 CFU / 100mL (Sterile) | ≤ 1 | ≤ 1 |

| USP Sterile WFI | ≤ 5 | ≤ 8 | ≤ 0.25 | 0 CFU / 100mL (Sterile) | ≤ 3 | ≤ 25 |

Tailored Solutions for Unique Production Needs

For customers with unique needs, we offer custom manufacturing to accommodate packaging, testing, and/or lot size requirements. Leverage our on-site single-use system (SUS) design and manufacturing coupled with continuous manufacturing capabilities to enhance your process needs.

Sizing Options

1,100L

200L

100L

50L

20L

10L